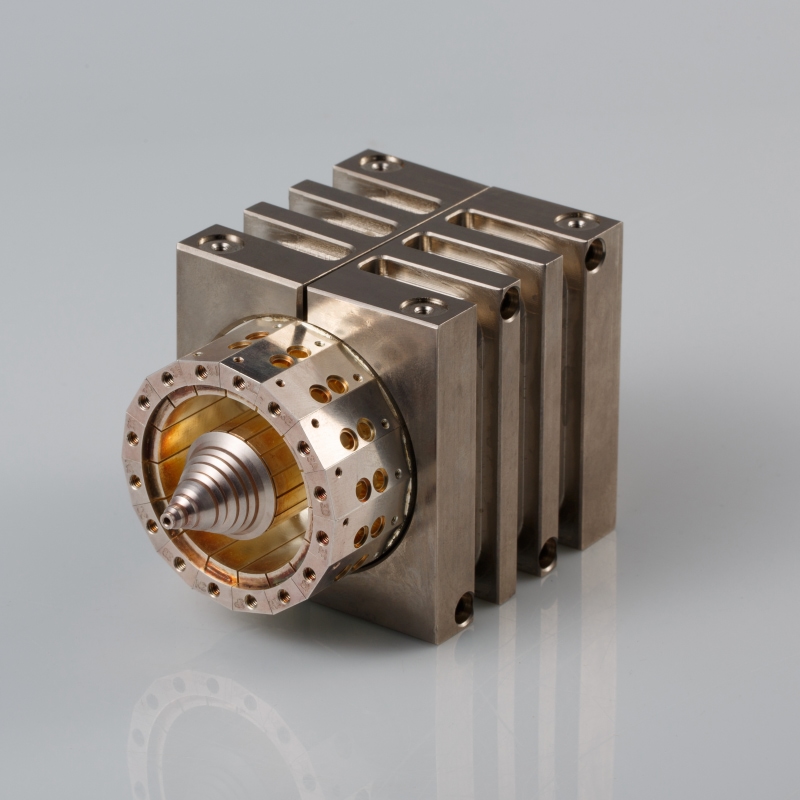

CNC machining a Bakin Karfe

Abubuwan da ake samu:

Bakin Karfe 304/304L| 1.4301/1.4307| X5CrNi18-10:Bakin karfe 304 shine mafi yawan bakin karfe. Yana da gaske ba Magnetic karfe kuma shi ne kasa da lantarki da thermally conductive fiye da carbon karfe. Ana amfani da shi sosai saboda sauƙin samuwa a cikin siffofi daban-daban. Yana da machinable da walda. Sauran sunayen wannan karfe sune: A2 bakin karfe, 18/8 bakin karfe, UNS S30400, 1.4301. 304L bakin karfe shine ƙananan sigar carbon na bakin karfe 304.

Bakin Karfe 316/316L | 1.4401/1.4404 | X2CrNiMo17-12-2:Bakin karfe na biyu da aka fi amfani da shi bayan 304, babban maƙasudin austenitic bakin karfe 316 yana da juriya na lalata musamman a cikin chloride mai ɗauke da mahalli da ingantaccen ƙarfin zafin jiki. Ƙananan nau'in carbon 316L yana da mafi kyawun juriya na lalata a cikin tsarin walda.

Bakin Karfe 303 | 1.4305 | X8CrNiS18-9:Grade 303 shine mafi sauƙin injuna na duk matakan austenitic na bakin karfe. Yana da m da machining gyara os bakin karfe 304. Wannan dukiya ne saboda mafi girma sulfur gaban a cikin sinadaran abun da ke ciki. Kasancewar sulfur yana inganta injina amma dan kadan rage juriyar lalata da taurin idan aka kwatanta da na bakin karfe 304.

Ƙididdiga na bakin karfe

Bakin ƙarfe nau'in ƙarfe ne na ƙarfe wanda aka yi daga haɗin ƙarfe da aƙalla 10.5% chromium. Yana da matukar juriya ga lalata, yana sa ya dace da aikace-aikace iri-iri, gami da likitanci, masana'antu na sarrafa kansa da sabis na abinci. Abubuwan da ke cikin chromium a cikin bakin karfe yana ba shi kaddarorin musamman da yawa, gami da ƙarfin ƙarfi da ductility, kyakkyawan juriya na zafi da kaddarorin marasa maganadisu. Bakin karfe yana samuwa a cikin nau'i-nau'i masu yawa, kowannensu yana da kaddarorin daban-daban don dacewa da aikace-aikace daban-daban. A matsayin shagon injin injin CNC a China. Ana amfani da wannan kayan a ko'ina a ɓangaren injin.

Amfanin bakin karfe

1. Karfe - Bakin karfe abu ne mai wuyar gaske kuma mai dorewa, yana mai da shi juriya ga hakora da karce.

2. Juriya na Lalacewa - Bakin ƙarfe yana da juriya na lalata, ma'ana ba zai lalata ko tsatsa ba idan aka fallasa shi ga danshi ko wasu acid.

3. Low Maintenance - Bakin karfe yana da sauƙin tsaftacewa da kulawa. Ana iya goge shi da rigar datti kuma baya buƙatar kowane maganin tsaftacewa na musamman ko goge goge.

4. Cost - Bakin karfe shine gabaɗaya mafi tsada-tasiri fiye da sauran kayan kamar marmara ko granite.

5.Versatility - Bakin karfe za a iya amfani dashi don aikace-aikace iri-iri, a cikin gida da waje. Hakanan ana samunsa ta nau'ikan ƙarewa da salo iri-iri, yana mai da shi kyakkyawan zaɓi ga kowane gida.

Ƙarfin ƙarfi mai ƙarfi, lalata da juriya na zafin jiki. Bakin karfe gami da babban ƙarfi, ductility, lalacewa da lalata juriya. Ana iya walda su cikin sauƙi, injina da goge su a cikin ayyukan injin cnc.

| Bakin Karfe 304/304L | 1.4301 | Saukewa: X5CrNi18-10 |

| Bakin Karfe 303 | 1.4305 | Saukewa: X8CrNiS18-9 |

| Bakin karfe 440C | 1.4125 | Saukewa: X105CrMo17 |

Yadda Bakin Karfe a CNC machining sassa

Bakin karfe sanannen zaɓi ne don sassan injinan CNC saboda ƙarfinsa, ƙarfinsa, da juriya na lalata. Ana iya sarrafa shi zuwa maƙasudin haƙuri kuma yana samuwa a cikin nau'o'in maki da ƙare. Ana amfani da bakin karfe a cikin masana'antu daban-daban, azaman samfuri mai sauri daga likitanci zuwa sararin samaniya, kuma yana da kyau don aikace-aikacen da ke buƙatar babban matakin karko da juriya na lalata."

Abin da CNC machining sassa na iya amfani da bakin karfe abu

Mafi yawan sassan injin CNC na kayan aikin bakin karfe sun haɗa da:

1. Gishiri

2. Shafi

3. Bushewa

4. Kulle

5. Kwayoyi

6. Masu wanki

7. Masu sarari

8. Matsala

9. Gidaje

10. Baka

11. Fasteners

12. Zafi Namiji

13. Kulle Zobba

14. Matsala

15. Masu haɗawa

16. Fitowa

17. Adafta

18. Bawuloli

19. Kayan aiki

20. Manifold"

Wani irin jiyya na saman ya dace da sassan mashin din CNC na bakin karfe

Mafi na kowa surface jiyya ga CNC machining sassa na bakin karfe abu ne sandblasting, passivation, electroplating, Black oxide, Zinc plating, Nickle plating, Chrome plating, Foda shafi, QPQ da kuma zanen. Dangane da takamaiman aikace-aikacen, ana iya amfani da wasu jiyya kamar etching sinadarai, zanen Laser, fashewar ƙwanƙwasa da goge goge.