Ƙarfin sabis ɗin mu na CNC

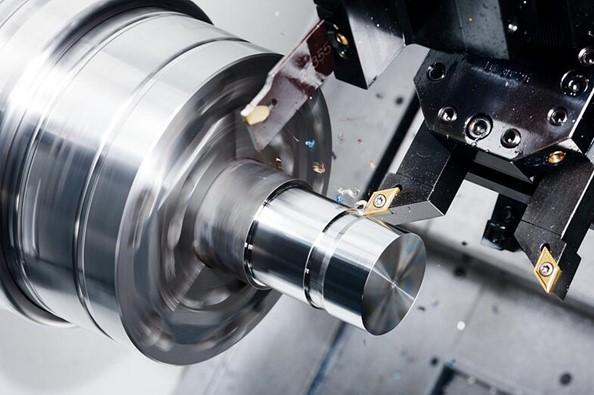

From prototyping to full production runs. Our wide range of CNC lathes and turning centers will allow you to produce highly accurate, high quality parts to meet even your most complex requirements. Can’t decide which machining process is best for you? Just send us drawing by email:rfq@lairun.com.cn

Farashin CNC

Injin jujjuyawar CNC suna iya samar da sassa masu ƙarancin farashi don sauƙi na geometric na cylindrical. Tsarin jujjuyawar CNC ɗin mu yana samar da samfuran al'ada da sassan samarwa na ƙarshe cikin sauri kamar 1 rana. Muna amfani da lathe CNC tare da kayan aiki mai rai don haka ana iya yin abubuwa kamar axial da ramukan radial, filaye, tsagi, da ramummuka.

Ana yawan amfani da juyawa CNC don:

Samfuran aiki da sassan amfani na ƙarshe

Sassan da ke da siffofi na silinda

Sassan da ke da ramukan axial da radial, filaye, tsagi, da ramummuka

Sassan tare da shafts, Valves, Lock Rings da Silinda.

Muna ba da amsa mai sauri don tabbatar da cewa an inganta sashin ku don tsarin juya CNC kuma ya dace da buƙatun da kuke buƙata. Maƙeran mu na iya isar da ɓangarorin juzu'in ƙarfe da filastik CNC don saurin samfur. wer da saurin gudu wanda ke shafar nau'ikan sassan da za'a iya yin tattalin arziki akansa.

Menene CNC Juyawa? Yaya Aiki yake?

● Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙadda tọn na Ƙadda ) na Ƙaddamar da ke Gudanarwa ne wanda ke amfani da lathe don ƙirƙirar daidaitattun sassa na al'ada daga abubuwa daban-daban, irin su karfe, filastik, da aluminum. Injin lathe yana jujjuya aikin aikin yayin da kayan aikin yankan ya siffata shi zuwa girman da sifar da ake so.

●Tsarin juyawa na CNC yana farawa tare da ƙirar da aka ƙirƙira ta amfani da software na Taimakon Kwamfuta (CAD). Ana canza ƙirar zuwa lambar da CNC lathe za ta iya karantawa da bi. Mai aiki yana saita na'ura ta hanyar loda kayan aikin a cikin lathe da shigar da kayan aikin da suka dace.

●Da zarar injin ya shirya, an ɗora shirin CNC, kuma mai aiki ya fara aikin. CNC lathe yana jujjuya aikin a cikin babban sauri yayin da kayan aikin yankan ke motsawa tare da kayan, cire wuce haddi abu har sai sashin ya kai siffar da ake so.

●CNC juyawa yana ba da fa'idodi da yawa akan jujjuyawar hannu na gargajiya. Na farko, daidaito da daidaito na juyawa CNC ya fi girma da jujjuyawar hannu. Wannan saboda an tsara na'urar CNC don bin ƙira daidai, yayin da jujjuyawar hannu ta dogara da fasaha da ƙwarewar mai aiki.

●Bugu da ƙari, juyawa CNC yana da sauri fiye da jujjuyawar hannu. Tare da lathe CNC, mai aiki na iya saitawa da gudanar da sassa da yawa a lokaci guda, yana haifar da ƙimar samarwa da yawa. Juyawar CNC shima yafi inganci, tare da ƙarancin sharar kayan abu da ƙarancin farashin aiki.

●A kantin injin mu na CNC, muna ba da sabis na juyawa CNC mai inganci mai inganci. Kayan aikin mu na zamani da ƙwararrun masu aiki suna ba mu damar ƙirƙirar sassa na al'ada tare da daidaito na musamman da sauri. Mun ƙware a samfuri kuma muna iya ɗaukar ƙanana da manyan ayyukan samarwa.

●A ƙarshe, CNC juya shi ne mai matukar inganci da ingantaccen tsarin masana'antu wanda zai iya samar da sassa na al'ada da sauri kuma tare da ma'auni na musamman. Ko kuna buƙatar samfur guda ɗaya ko babban aikin samarwa, juyawa CNC kyakkyawan zaɓi ne don buƙatun masana'anta.

Nau'in Lathes na CNC

Akwai nau'ikan lathes da yawa, amma waɗanda aka fi sani shine 2-axis CNC lathes da nau'in lathes na Swiss. Nau'in lathes na Swiss na musamman ne a cikin cewa ana ciyar da kayan haja ta hanyar bushing jagora, yana barin kayan aiki don yanke kusa da maƙasudin tallafi, wanda ke sa su da amfani musamman na dogon lokaci, sassan lathe CNC siririn da micromachining. Wasu lathes iri-iri na Swiss suma sun zo sanye da shugaban kayan aiki na biyu wanda ke aiki azaman aCNC inji, ƙyale su yin ayyuka da yawa na inji ba tare da matsar da kayan aiki zuwa wani na'ura daban ba. Wannan ya sa nau'ikan lathes na Swiss su zama masu tasiri sosai ga hadaddun sassan juyi tare da sabis na lathe CNC.

Nau'in Lathes na CNC

KamarCNC masana'antu, CNC lathes za a iya sauƙi kafa don high repeatability, wanda ya sa su girma ga duk abin da daga m prototyping zuwa low da high-girma samar. Cibiyoyin juyawa na CNC da yawa da lathes-nau'in Swiss suna ba da izini don ayyukan injina da yawa a cikin injin guda ɗaya. sanya su zaɓi mai tsada don haɗaɗɗun geometries waɗanda in ba haka ba zasu buƙaci injuna da yawa ko canje-canjen kayan aiki a cikin injin CNC na gargajiya.

Nau'in Lathes na CNC

●Idan kuna buƙatar babban inganci, sassa na al'ada da sauri, sabis ɗin juyawa na CNC ɗinmu babban zaɓi ne. A kantin injin mu na CNC, muna amfani da kayan aiki na zamani da ƙwararrun masu aiki don ƙirƙirar madaidaicin sassa tare da saurin gaske da daidaito.

● Ayyukan mu na juyawa na CNC mai sauri suna da kyau don yin samfuri da ƙananan ƙananan ƙananan samar da ƙarar girma. Mun ƙware wajen ƙirƙirar sassa na al'ada daga abubuwa daban-daban, gami da ƙarfe, filastik, da itace. Muna ba da nau'i mai yawa na ƙarewa, ciki har da aluminum anodized da PTFE.

● Tsarin mu na CNC yana farawa tare da ƙirar da aka yi ta amfani da software na CAD. Ana canza ƙirar zuwa lambar da CNC lathe za ta iya karantawa da bi. Mai aiki yana saita na'ura ta hanyar loda kayan aikin a cikin lathe da shigar da kayan aikin da suka dace.

● Da zarar na'urar ta shirya, mai aiki zai fara aikin. CNC lathe yana jujjuya aikin a cikin babban sauri yayin da kayan aikin yankan ke motsawa tare da kayan, cire wuce haddi abu har sai sashin ya kai siffar da ake so.

● Ayyukan mu na juyawa na CNC suna ba da fa'idodi da yawa. Na farko, za mu iya samar da sassa na al'ada da sauri, tare da ɗan gajeren lokacin jagora fiye da tsarin masana'antu na gargajiya. Bugu da ƙari, daidaitonmu da daidaito ba su daidaita ba, godiya ga kayan aikinmu na zamani da ƙwararrun masu aiki.

● Har ila yau, muna ba da kyakkyawar sabis na abokin ciniki da goyon baya a cikin dukan tsari. Daga ƙira zuwa bayarwa, muna aiki tare tare da abokan cinikinmu don tabbatar da cewa sun sami mafi kyawun sassa a cikin ɗan gajeren lokaci.

A ƙarshe, ingantattun ayyukan jujjuyawar CNC ɗin mu shine kyakkyawan zaɓi don buƙatun masana'anta. Ko kuna buƙatar samfur guda ɗaya ko babban aikin samarwa, za mu iya isar da sassa na al'ada cikin sauri kuma tare da madaidaici na musamman.

Matsakaicin iyakoki don juyawa CNC

| Iyakokin girman sashi | Ma'aunin awo | Raka'a na Imperial |

| Matsakaicin diamita na sashi | mm 431 | 17 in |

| Matsakaicin tsayin sashi | mm 990 | 39 in |

| Matsakaicin jujjuyawa akan abin hawa | 350 mm | 13.7 in |

| Matsakaicin igiya ta rami | 40 mm | 1.5 inci |

Rufin Foda

Anan akwai jerin daidaitattun kayan aikin injin mu na CNC da akwai.

Abubuwan da aka bayar na CNC Metals

| Filastik | Ƙarfafa Filastik |

| ABS | Garolite G-10 |

| Polypropylene (PP) | Polypropylene (PP) 30% GF |

| Nailan 6 (PA6 / PA66) | Nailan 30% GF |

| Delrin (POM-H) | FR-4 |

| Acetal (POM-C) | PMMA (Acrylic) |

| PVC | KYAUTA |

| HDPE | |

| UHMW PE | |

| Polycarbonate (PC) | |

| PET | |

| Teflon (PTFE) |

Haƙuri

Muna bin ka'idodin ISO 2768 don CNC Machining.

| Iyaka don girman ƙima | Filastik (ISO 2768-m) | Karfe (ISO 2768-f) |

| 0.5mm* zuwa 3mm | ± 0.1mm | ± 0.05mm |

| Fiye da 3mm zuwa 6mm | ± 0.1mm | ± 0.05mm |

| Fiye da 6mm zuwa 30mm | ± 0.2mm | ± 0.1mm |

| Fiye da 30mm zuwa 120mm | ± 0.3mm | ± 0.15mm |

| Fiye da 120mm zuwa 400mm | ± 0.5mm | ± 0.2mm |

| Fiye da 400mm zuwa 1000mm | ± 0.8mm | ± 0.3mm |

| Fiye da 1000mm zuwa 2000mm | ± 1.2mm | ± 0.5mm |

| Fiye da 2000mm zuwa 4000mm | ± 2mm |

- Da fatan za a nuna a fili jure haƙuri don girman ƙima da ke ƙasa da 0.5mm akan zanen ku na fasaha.

CNC juya zane jagororin

Teburin da ke ƙasa yana taƙaita ƙimar da aka ba da shawarar kuma masu yuwuwar fasaha don mafi yawan abubuwan da aka ci karo da su a sassan injinan CNC.

| Siffar | Girman da aka ba da shawarar | Girman mai yiwuwa |

| Min. girman fasalin | Ø 2.5 mm | Ø 0.5 mm |

| Gefuna na ciki | R8 mm | R 0.25 mm |

| Mafi ƙarancin kauri na bango | 0.8 mm (don karafa) | 0.5mm (don karafa) |

| 1.5mm (don filastik) | 1.0mm (don filastik) | |

| Ramuka | Diamita: daidaitattun girman bit ɗin rawar soja | Diamita: Ø 0.5 mm |

| Zurfin: 4 x diamita | Zurfin: 10 x diamita | |

| Zaren | Girman: M6 ko mafi girma | Girman: M2 |

| Tsawon: 3 x diamita |