Abin da aka mutu simintin

Die simintin gyare-gyare tsari ne na masana'antu da ake amfani da shi don samar da sassa na ƙarfe tare da daidaito mai girma da ƙarewar saman. Ya ƙunshi tilasta narkakkar karfe zuwa cikin kogon ƙura a ƙarƙashin babban matsi. An ƙirƙiri rami mai ƙura ta ƙarfe mai tauri guda biyu waɗanda aka kera su zuwa siffar da ake so.

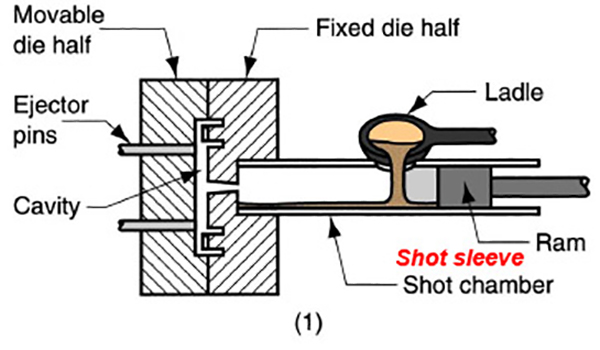

Tsarin yana farawa da narkewar ƙarfe, yawanci aluminum, zinc, ko magnesium, a cikin tanderu. Daga nan ana allurar da narkakken ƙarfen a cikin ƙura a matsa lamba mai ƙarfi ta amfani da latsa ruwa. Ƙarfe yana ƙarfafa da sauri a cikin ƙirar, kuma an buɗe rabi biyu na ƙirar don sakin ɓangaren da aka gama.

Die simintin ana amfani da ko'ina don samar da sassa tare da hadaddun siffofi da kuma bakin ciki bango, kamar injin tubalan, watsa gidaje, da daban-daban mota da kuma aerospace sassa. Hakanan tsarin ya shahara wajen kera kayan masarufi, kamar kayan wasan yara, kayan girki, da na'urorin lantarki.

Matsa lamba Die Casting

Die simintin gyare-gyaren tsari ne na musamman wanda ya bunƙasa mafi yawa a cikin ƙarni na 20. Tushen tsari ya ƙunshi: narkakken ƙarfe ana zuba/ allura a cikin ƙera ƙarfe kuma ta hanyar babban sauri, matsa lamba mai ƙarfi (a cikin matsi mutu simintin) da sanyaya narkakken ƙarfe yana ƙarfafa don samar da ingantaccen simintin. Yawanci, tsarin da kansa yana ɗaukar ƴan daƙiƙa kaɗan kawai kuma hanya ce mai sauri ta ƙirƙirar samfurin ƙarfe daga ɗanyen abu. Die simintin ya dace da kayan kamar gwangwani, gubar, zinc, aluminium, magnesium zuwa gami da jan ƙarfe har ma da ƙarfe irin su bakin karfe. Babban abubuwan haɗin da ake amfani da su a yau a cikin simintin matsi na mutuwa sune aluminum, zinc da magnesium. Daga na'urorin simintin farko na mutuwa waɗanda ke daidaita kayan aikin mutu a tsaye zuwa daidaitattun daidaitattun daidaito da aiki na yau da kullun, ɗaure taye huɗu da cikakkun matakan sarrafa kwamfuta tsarin ya ci gaba tsawon shekaru.

Masana'antar ta girma ta zama na'ura mai ƙera a duniya, tana yin abubuwa don aikace-aikace iri-iri, waɗanda da yawa daga cikinsu za su iya isa ga kansu kamar yadda aikace-aikacen samfuran simintin mutuwa ya bambanta.

Amfanin matsa lamba mutu simintin

Kadan daga cikin fa'idodin yin babban matsa lamba mutu simintin:

• Tsarin ya dace da samar da girma mai girma.

Ƙirƙirar simintin gyare-gyare masu sauƙi da sauri idan aka kwatanta da sauran hanyoyin samar da ƙarfe (misali machining).

• Babban ƙarfin abubuwan da aka samar a cikin yanayin simintin simintin gyare-gyare (batun ƙirar kayan aiki).

• Matsakaicin maimaitawa.

• Sassan bango na bakin ciki mai yiwuwa (misali 1-2.5mm).

• Kyakkyawan haƙuri na layi (misali 2mm/m).

• Kyakkyawan gamawa (misali 0.5-3 µm).

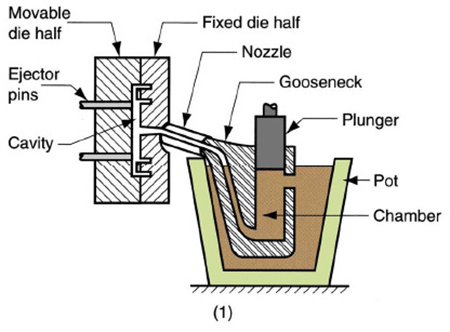

Saboda wannan "rufe" karfe narke/tsarin allura da ƙaramin motsi na injin zafi mai zafi mutu simintin zai iya samar da mafi kyawun tattalin arziki don samarwa. Zinc karfe gami ne da farko amfani da zafi dakin matsa lamba mutu simintin gyaran kafa wanda yana da fairly low narkewa batu wanda bayar da ƙarin fa'ida ga low lalacewa a kan inji (tukunya, gooseneck, hannun riga, plunger, bututun ƙarfe) da kuma low lalacewa a kan mutu kayan aikin (don haka tsawon kayan aiki rayuwa idan aka kwatanta da aluminum mutu simintin kayan aikin - batun simintin ingancin yarda).

Injin ɗakin ɗakin sanyi sun dace da simintin gyare-gyare na aluminum, sassa akan injin (hannun harbi, tukwici) ana iya maye gurbinsu na tsawon lokaci, hannayen riga na iya zama ƙarfe don ƙara ƙarfin su. Aluminum alloy yana narke a cikin yumbu crucible saboda aluminium dangi high narkewa batu da kuma bukatar rage hadarin da ƙarfe karba wanda shi ne hadari a cikin ferrous crucibles. Saboda aluminum wani ɗan ƙaramin ƙarfe ne mai sauƙi yana ba da damar yin simintin simintin gyare-gyare masu girma da nauyi ko kuma inda ake buƙatar ƙarin ƙarfi da haske a cikin simintin gyare-gyare.