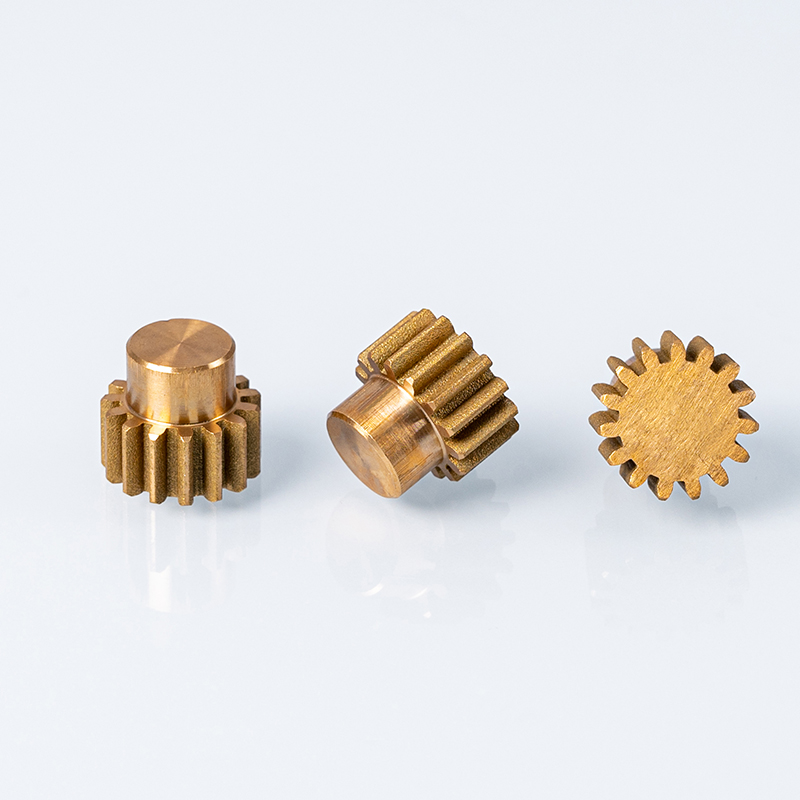

CNC machining a cikin jan karfe sassa na likita

Ƙayyadaddun sassan mashin ɗin CNC tare da Material Copper

Copper kuma ba maganadisu ba ne kuma ba mai walƙiya ba, yana mai da shi dacewa don amfani da kayan aikin likitanci waɗanda ke fallasa igiyoyin lantarki ko filaye masu ƙarfi.Copper kuma yana da juriya na lalata, wanda ya sa ya zama babban zaɓi ga kayan aikin likita waɗanda ke fallasa ruwa ko wasu ruwaye.CNC machining a cikin jan karfe yana ba da damar samar da hadaddun, sassa masu mahimmanci tare da babban matakin daidaito da daidaito.Za a iya sarrafa sassan jan ƙarfe zuwa ainihin ƙayyadaddun bayanai da haƙuri, tabbatar da cewa kayan aikin likita suna da aminci da inganci.

1. Kayan Tagulla: C110 (99.9% Copper)

2. Tsari: CNC Machining

3. Haƙuri: +/-0.01mm

4. Gama: Halitta 5. Aikace-aikace: An yi amfani da shi a cikin kayan lantarki, lantarki, hasken wuta da sauran masana'antu.

Amfanin CNC machining Copper

CNC machining jan karfe yana ba da fa'idodi da yawa, irin su daidaitattun daidaito da daidaito, madaidaicin ƙarfi-da-nauyi rabo, mai kyau thermal da lantarki watsin, ƙara lalata juriya idan aka kwatanta da sauran karafa, girma da kwanciyar hankali a kan fadi da zafin jiki kewayon, rage inji lokaci saboda ta. malleability da sauƙi na machinability.

1. Ƙarfi mafi girma da karko - Copper abu ne mai mahimmanci kuma yana iya tsayayya da yanayin zafi, matsa lamba da lalacewa.Wannan ya sa ya zama kyakkyawan zaɓi don aikace-aikacen mashin ɗin CNC, kamar yadda za'a iya amfani da shi a cikin aikace-aikace iri-iri kuma yana iya jure wa ƙayyadaddun ayyukan maimaitawa, madaidaicin mashin aiki.

2. Excellent thermal watsin - Copper's kyau kwarai thermal watsin sanya shi manufa domin CNC machining aikace-aikace da bukatar daidaici yankan da hakowa ayyukan.Wannan yana tabbatar da cewa samfurin da aka gama zai sami mafi girman matakin daidaito da daidaito.

3. Babban ƙarfin wutar lantarki - Wannan fasalin yana sa jan ƙarfe ya zama kayan aiki mai kyau don ayyukan aikin CNC da ke buƙatar haɗin wutar lantarki ko sassan.

4. Cost-tasiri - Copper ne kullum kasa tsada fiye da sauran karafa, yin shi da cikakken zabi ga CNC machining ayyukan da bukatar babban adadin sassa ko aka gyara.

5. Sauƙi don yin aiki tare da - Copper abu ne mai sauƙi don yin aiki tare, yana ba da damar samar da sauri da daidaito mafi girma.

Yadda Copper a CNC machining sassa

CNC machining jan karfe ya ƙunshi yin amfani da madaidaicin kayan aikin yankan kamar injina na ƙarshe don cire kayan aiki daga kayan aikin bisa ga hanyar da aka tsara.Ana yin shirye-shirye don mashin ɗin CNC ta hanyar software mai taimakon kwamfuta (CAD) sannan a tura shi zuwa injin ta hanyar G code, wanda ke ba shi damar sarrafa kowane motsi bi da bi.Za a iya toshe sassan jan ƙarfe, niƙa ko juya dangane da aikace-aikacen.Hakanan ana amfani da ruwan ƙarfe na ƙarfe yayin aiwatar da aikin injina na CNC, musamman lokacin da ake mu'amala da ƙarfe masu ƙarfi kamar jan ƙarfe waɗanda ke buƙatar ƙarin lubrication.

CNC machining jan karfe tsarin aiki ne na yin amfani da injinan sarrafa lambobi (CNC) don siffanta kayan jan karfe.Ana amfani da Copper a cikin aikace-aikacen CNC iri-iri da suka haɗa da samfuri, ƙira, gyare-gyare, da sassan amfani na ƙarshe.

CNC machining jan karfe yana buƙatar amfani da software na musamman da injinan CNC waɗanda ke da kayan aikin da suka dace don yanke da siffar kayan daidai.Tsarin yana farawa ta hanyar ƙirƙirar ƙirar 3D na ɓangaren da ake so a cikin shirin CAD.Ana canza samfurin 3D zuwa hanyar kayan aiki, wanda shine tsarin umarni wanda ke tsara na'urar CNC don samar da siffar da ake so.

Ana ɗora injin ɗin CNC tare da kayan aikin da suka dace, kamar masana'anta na ƙarshe da ƙwanƙwasa, sannan an ɗora kayan a cikin injin.Sa'an nan kuma ana sarrafa kayan bisa ga hanyar kayan aiki da aka tsara kuma an samar da siffar da ake so.Bayan an gama aikin injin, ana bincika sashin don tabbatar da ya dace da ƙayyadaddun bayanai.Idan ya cancanta, an gama sashin da nau'ikan hanyoyin sarrafa kayan aiki kamar buffing da goge baki.

Abin da CNC machining sassa na iya amfani da Copper

CNC machining jan karfe sassa za a iya amfani da iri-iri na aikace-aikace, ciki har da lantarki sassa da haši, high-madaidaicin mota sassa, aerospace kayayyakin, likita kayan aiki, hadaddun inji taro da sauransu.Abubuwan da ake amfani da su na Copper CNC galibi ana yin su da wasu karafa don inganta haɓaka aiki ko juriya.

CNC machining jan karfe sassa za a iya amfani da iri-iri na aikace-aikace, ciki har da lantarki haši, motor gidaje, zafi musayar, ruwa ikon sassa, tsarin gyara, da kuma kayan ado.Sassan jan ƙarfe suna da kyau don injin CNC saboda ƙarfin wutar lantarki da ƙarfin zafi, da kyakkyawan juriya na lalata.CNC machining jan karfe kuma za a iya amfani da su haifar da rikitaccen siffofi da sassa tare da daidai tolerances.

Wani irin jiyya na saman ya dace da sassan mashin din CNC na Copper

Mafi dacewa saman jiyya ga CNC machining jan karfe sassa ne anodizing.Anodizing wani tsari ne wanda ya ƙunshi electro da sinadaran maganin karfe da samar da oxide Layer a saman kayan wanda ke kara karfin juriya da kariyar lalata.Hakanan za'a iya amfani dashi don samar da kayan ado na ado kamar launuka masu haske, matte gama ko sautuna masu haske.

Gabaɗaya ana kula da alluran jan ƙarfe tare da plating na nickel mara amfani, anodizing, da wucewa don kare farfajiya daga lalacewa da lalacewa.Hakanan ana amfani da waɗannan hanyoyin don inganta kyawun sashin.

Aikace-aikace:

3C masana'antu, kayan ado na haske, kayan lantarki, sassa na mota, sassan kayan daki, kayan aikin lantarki, kayan aikin likita, kayan aikin sarrafa kai tsaye, sauran sassan simintin ƙarfe.